Silica is a naturally occurring mineral found in materials like sand, quartz, and granite. While it’s commonly encountered in various industries, its microscopic particles can pose severe health risks when inhaled. Awareness about silica exposure is crucial to safeguarding employee health. Here’s a detailed look at the dangers of silica and effective measures to ensure workplace safety.

The Dangers of Silica Exposure

Health Hazards:

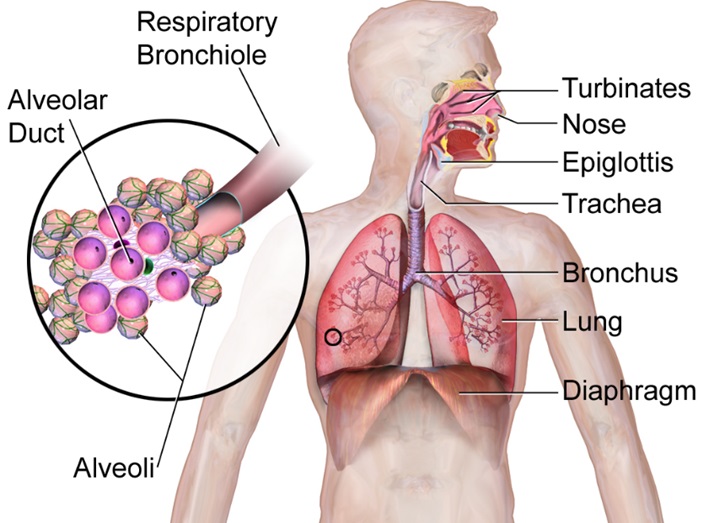

1. Respiratory Issues: Inhaling silica dust can lead to serious respiratory problems such as silicosis—a lung disease causing scarring and reduced lung function.

2. Chronic Conditions: Prolonged exposure may result in chronic obstructive pulmonary disease (COPD), lung cancer, and kidney disease.

3. Silicosis Risk Groups: Those most at risk include workers in construction, mining, manufacturing, and industries involving cutting, grinding, or drilling of materials containing silica.

Protecting Your Employees

Risk Assessment:

1. Identify Potential Exposure: Assess job tasks involving silica-containing materials to determine potential risks.

2. Monitoring Exposure Levels: Regularly measure silica dust levels in the workplace to gauge exposure risks.

Engineering Controls:

1. Substitution: Where possible, substitute silica-containing materials with safer alternatives.

2. Ventilation: Use proper ventilation systems, such as local exhaust ventilation, to capture silica dust at its source.

3. Enclosures: Employ enclosures or barriers to contain dust during high-risk activities.

Administrative Controls:

1. Training and Education: Provide comprehensive training on silica hazards, proper handling of materials, and the use of personal protective equipment (PPE).

2. Work Practices: Implement safe work practices like wet methods to control dust and reduce airborne silica particles.

3. Rotation and Limitation: Rotate employees to minimise prolonged exposure and limit the duration of work in high-risk areas.

Personal Protective Equipment (PPE):

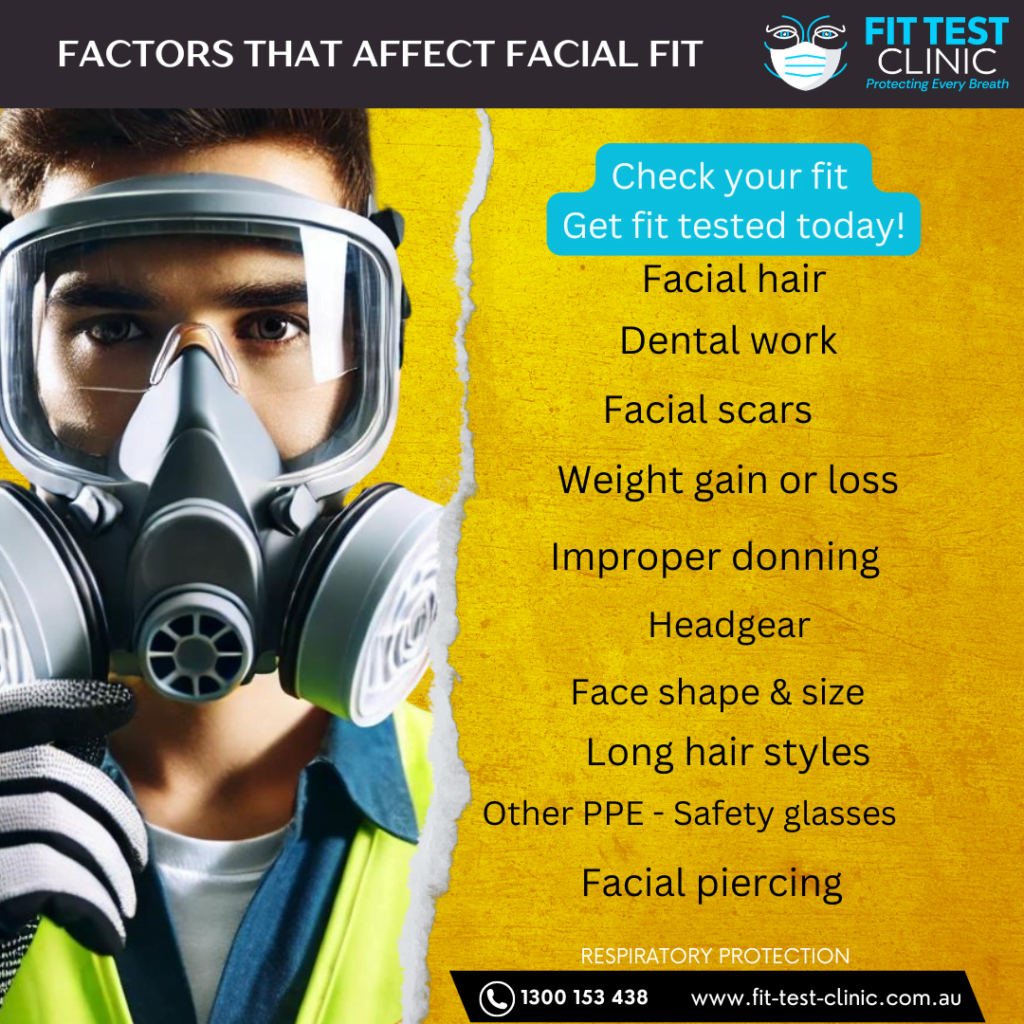

1. Respiratory Protection: Provide NIOSH-approved respirators for tasks with high silica exposure.

2. Protective Clothing: Outfit workers with appropriate clothing to prevent skin contact and reduce the risk of contamination.

Ensuring Compliance and Safety Culture

Regulatory Compliance:

1. Understand Regulations: Familiarize yourself with local occupational health and safety regulations related to silica exposure.

2. Regular Compliance Checks: Conduct routine inspections and audits to ensure adherence to safety protocols.

Promoting Awareness and Participation:

1. Open Communication: Encourage employees to report unsafe conditions or concerns regarding silica exposure.

2. Training Updates: Keep training programs up to date and incorporate new information on silica safety measures.

Conclusion

Silica exposure is a serious occupational hazard that requires proactive measures to safeguard employee health. By implementing comprehensive risk assessments, engineering and administrative controls, providing necessary PPE, ensuring regulatory compliance, and fostering a safety-centric culture, companies can significantly reduce the risks associated with silica exposure and create a healthier work environment for their employees.

For detailed and specific references on silica exposure and safety measures, I recommend consulting sources such as:

- OSHA’s Silica Page: https://www.osha.gov/silica/

- NIOSH’s Silica Publications: https://www.cdc.gov/niosh/topics/silica/pubs.html

- Occupational Health and Safety Guidelines related to silica exposure

- Academic papers and publications on occupational health and workplace safety

Remember, protecting your employees from silica isn’t just a legal obligation—it’s a moral responsibility that contributes to their well-being and the overall success of your organisation. Speak to our team about a course for your employees.