Fit Test Report

A fit test report is crucial for both compliance and the safety of the wearer in several ways:

Compliance with Health and Safety Standards

In industries where workers are exposed to hazardous substances like silica or asbestos, compliance with safety regulations, such as Australian/New Zealand Standard, Selection, use and maintenance of respiratory protective equipment 1715:2009, is mandatory. A fit test report documents that a quantitative or qualitative fit test has been conducted properly, ensuring that the respirator provides an adequate seal to the wearer’s face. This documentation helps organizations demonstrate that they are meeting regulatory requirements and protecting workers from inhaling dangerous contaminants.

Verification of Proper Respirator Use

The fit test report ensures that the worker is using the same make, model, size, and style of respirator in their daily tasks that they were tested in. This is vital because the effectiveness of the respirator depends on it fitting the individual correctly. If a worker switches to a different respirator, the fit may no longer be effective, leaving them exposed to potential hazards. The report acts as a record, confirming that the correct respirator was tested and must continue to be used to ensure ongoing protection.

Mitigating Risks of Incorrect Usage

Having a fit test report can help identify any issues related to improper fit, allowing corrective measures to be taken before the wearer is exposed to harmful environments. It ensures that the wearer knows how to don and use the respirator correctly, which is critical for their health and safety.

Audit and Record-Keeping

The fit test report serves as a key document during audits or inspections by health and safety regulators. It provides proof that a company is proactive in maintaining worker safety, which helps avoid potential fines or legal repercussions. Keeping these records ensures that companies have evidence of compliance over time, which is often required for health and safety audits or incident investigations.

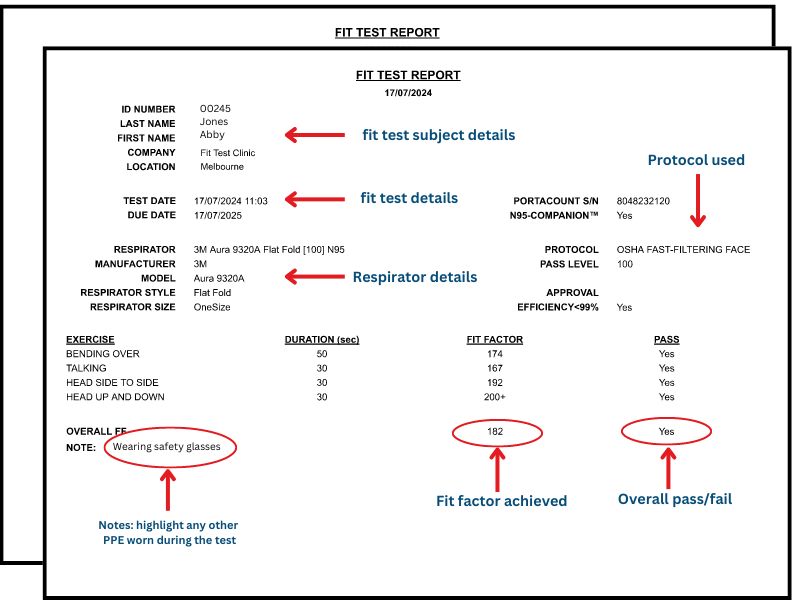

You will receive a fit test report to demonstrate your compliance with the Respiratory Protection Program. As show below the details include;

- Fit Test Subject details

- Respirator details

- Test details

Importance of Documenting PPE in Fit Test Reports

Ensures Proper Replication of Fit: When conducting a fit test, it’s essential to document all the personal protective equipment (PPE) worn during the test—such as safety goggles, earmuffs, or helmets—because these items can interfere with the fit of the respirator. Any PPE that touches or comes close to the respirator may affect the seal, and documenting what was used ensures that the same conditions can be replicated in the worker’s daily tasks. If the worker changes or adds PPE later that wasn’t used during the fit test, it could compromise the respirator’s effectiveness.

Prevents Misuse of Respiratory Protection: Recording the exact PPE worn during the fit test helps avoid confusion about how to wear the respirator in combination with other protective gear. The fit test report serves as a reference for the worker and the safety officer to ensure the worker is not unintentionally altering the fit when donning other PPE. This documentation ensures the worker follows the same steps in daily use that were followed during the fit test, preventing unsafe practices.

OSHA Protocol

Australia has adopted a similar approach to fit testing as the OSHA regulations in the United States, specifically in relation to quantitative fit testing (QNFT) and qualitative fit testing (QLFT). The protocols described by OSHA in 29 CFR 1910.134 are recognised and adapted in Australia to ensure accurate respirator fit-testing. In summary, making detailed notes about PPE and the protocol used in a fit test report is essential for ensuring the accuracy, consistency, and compliance of the test. It helps prevent potential errors in daily respirator use and ensures that the test is repeatable under the same conditions. By using the OSHA-approved protocols in fit testing, Australia aligns with global best practices for protecting workers from respiratory hazard.